Clean room manufacturing

Injection molding

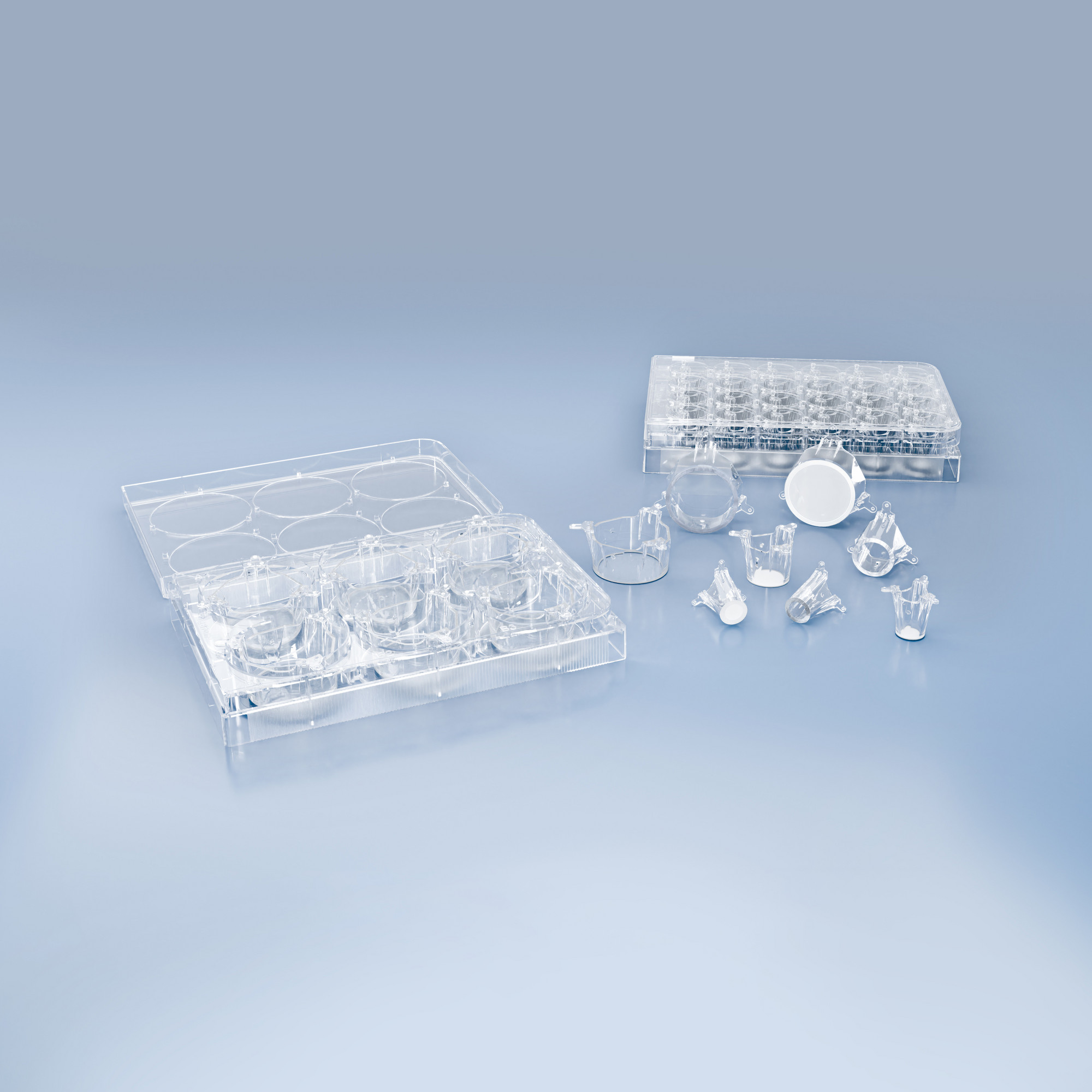

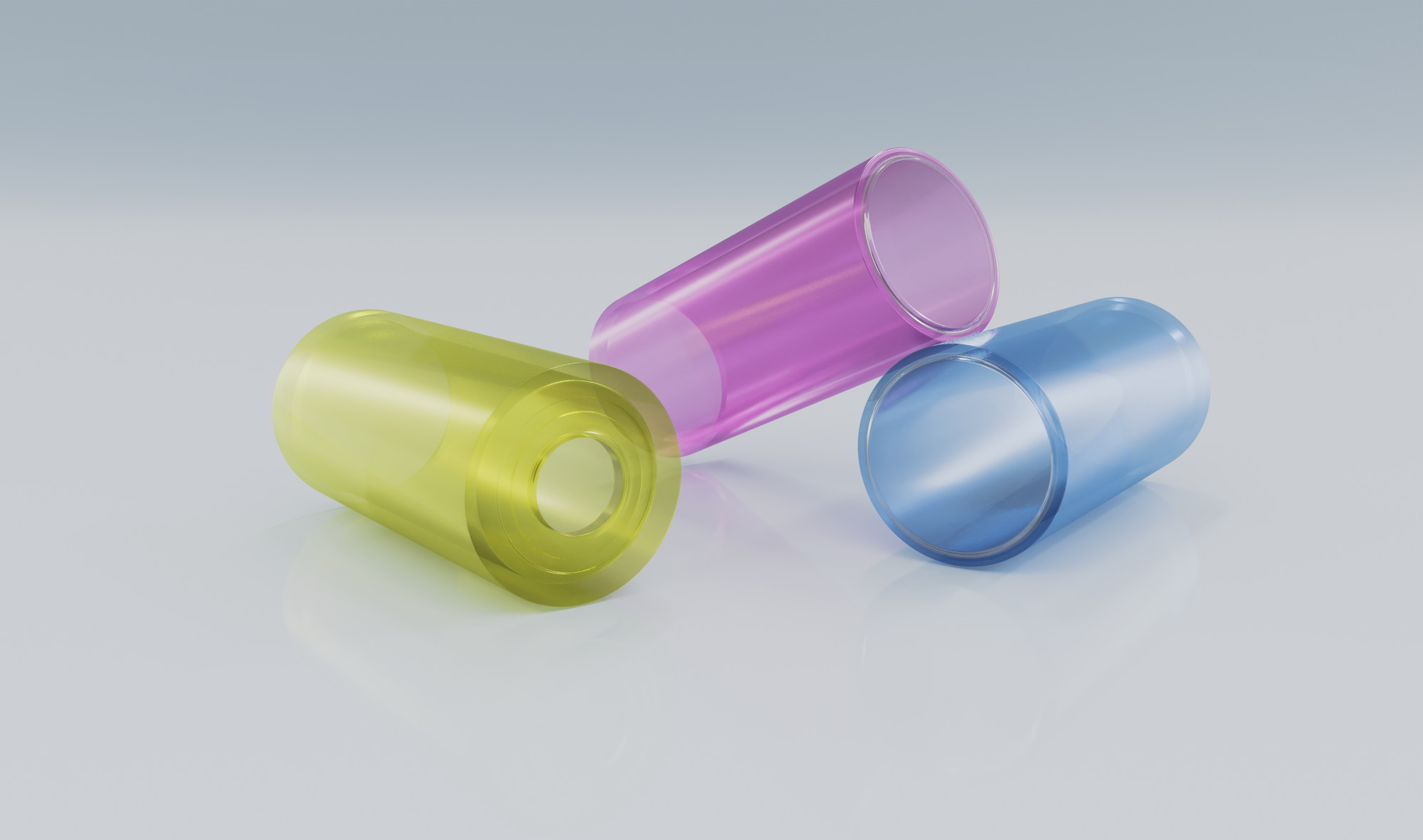

As a system supplier for the medical technology, biotechnology, laboratory diagnostics and packaging industries, we stand and both for diligence as well as efficiency in the processing of plastic components and membranes. The reproducible manufacture of components in high numbers using ultra-modern, all-electric injection molding machines is one of our core competencies and allows the manufacture of components with the highest degree of precision. The subsequent assembly and customization are fully integrated in our plants.

The procedures include multi-component injection molding, in-mold decoration (IMD, IMF), injection embossing, thin-wall molding, micro-molding and extrusion. Production takes place in ISO class 8 clean rooms as well as controlled areas using injection molding machines between 100 and 2,750 kilo newton.

Filter membranes

As a specialist in the development of custom manufactured track etched membranes, we are one of the world‘s very few in the industry with such know-how.

For our TRAKETCH® Membranes ultra-thin plastic films are bombarded with accelerated heavy ions, further processed and then chemically etched.

The diameter of the resulting pore channels can be determined with micrometer accuracy and are precisely processed in clean room manufacturing. In an in-line process, this is continuously controlled throughout the production process.