Particle filtration and separation

TRAKETCH® Membranes for media preparation

A vast range of technical systems require preparation, i.e. the filtration and separation of particles as well as gassy or liquid media.

The prepared media are permanently quality checked by highly precise quality sensors, which ensure that only particles in a defined size remain in the prepared media. Our microporous TRAKETCH® Filter Membranes (PFOA/PFCA-free & PFAS-free upon request) are optimum as so-called particle filters thanks to their adjustable pore sizes of 0.08 µm to 20 µm, especially for these quality sensor applications.

A wide range of environmental analysis processes are other scopes of application, such as those aiming at the detection of microplastics in purified water or the analysis of particulate matter in the air. The smooth surface structure of the microporous TRAKETCH® Filter Membranes, unlike depth filter membranes, provides an excellent solution for the particle analysis on the membrane surface.

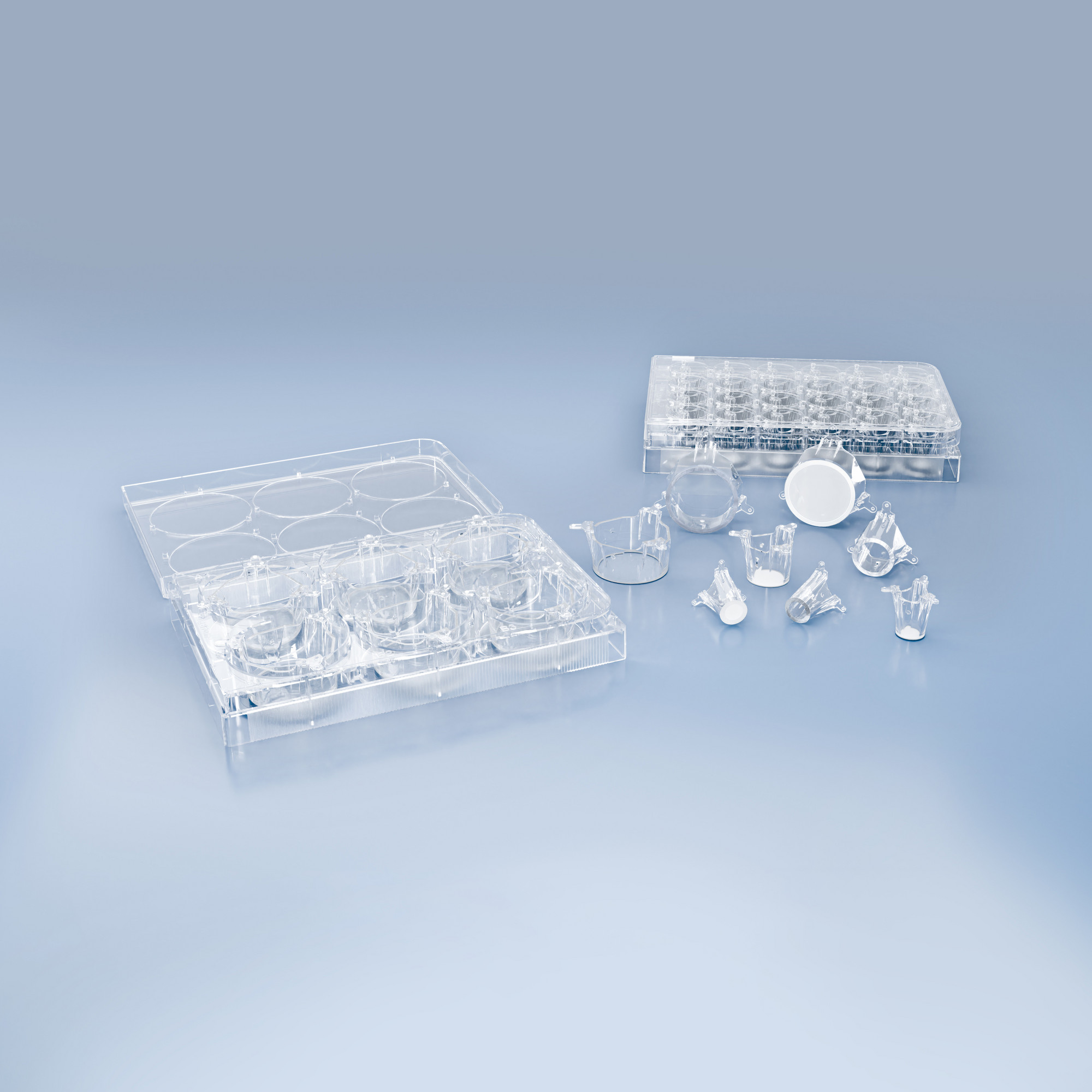

Our product portfolio ranges from membranes on rolls to preassembled membrane components to the development of complex component groups in combination with plastic injection molds.

Product solutions and configurations

Injection molding and filtration are our passion. In these areas we develop products based on customer specifications, manufacture serial products and resolve current challenges to offer best solutions. To that end, we partner with you from the start in the development process from the initial idea to the series production of your component.

- Membranes on rolls

- Preassembled membranes

- TRAKETCH® adhesiveVENTpads

- Injection molded membrane parts

- Complex components and component groups

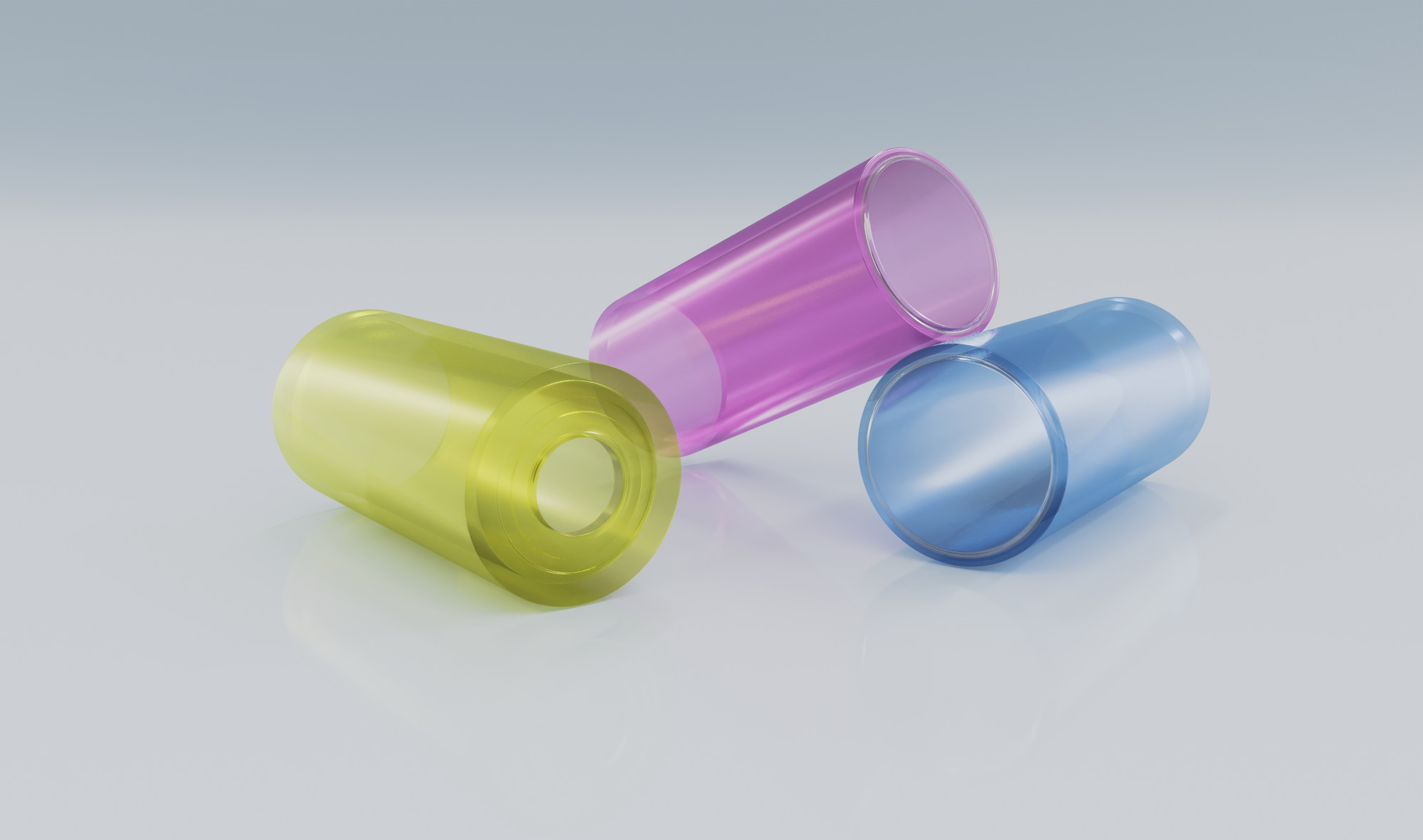

- Shape-related standard products under our off-the-shelf FLUXX® brand.

For additional information visit FLUXX® Degassing Inserts

Application examples

- Air quality sensors, for instance for the vacuum air of engines or ventilation systems in the automotive sector

- Environmental analyses: Microplastics in water purification or particulate matter analyses of the air

- Clean room system emissions protection

- Water filtration

- Paint shop systems

- Sewage analyses

- Exhaust gas purification systems

- Moisture and liquid sensors

- Filter efficiency tests

- Analysis of process exhaust gas

- Analysis of atmospheric aerosols

- Sterile particle separation.

See also SABEU's solutions medical technology and life sciences.

Your contact person

Kevin Eckert

Head of FLUXX

Packaging & Industrial